WEMA – Tool management, tool maintenance supports the requirements of ISO 9001:2015 and IATF 16 949.

WEMA is an easy-to-use database that we developed in cooperation with toolmaking experts and the IFU Institute and which has been used by numerous companies for many years.

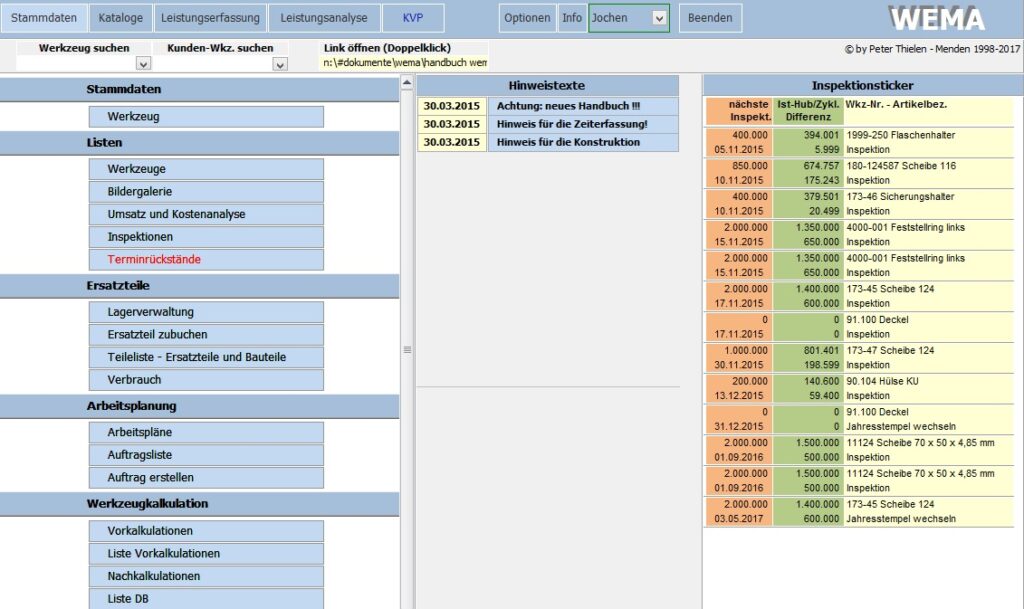

WEMA offers the following functions:

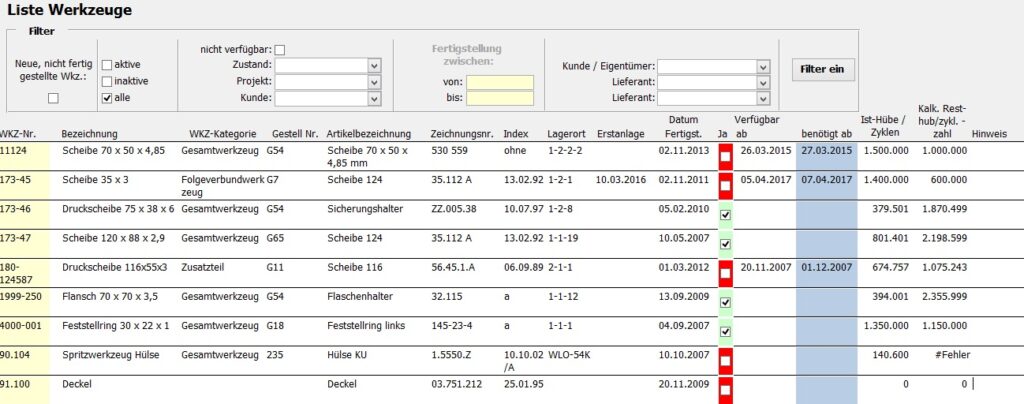

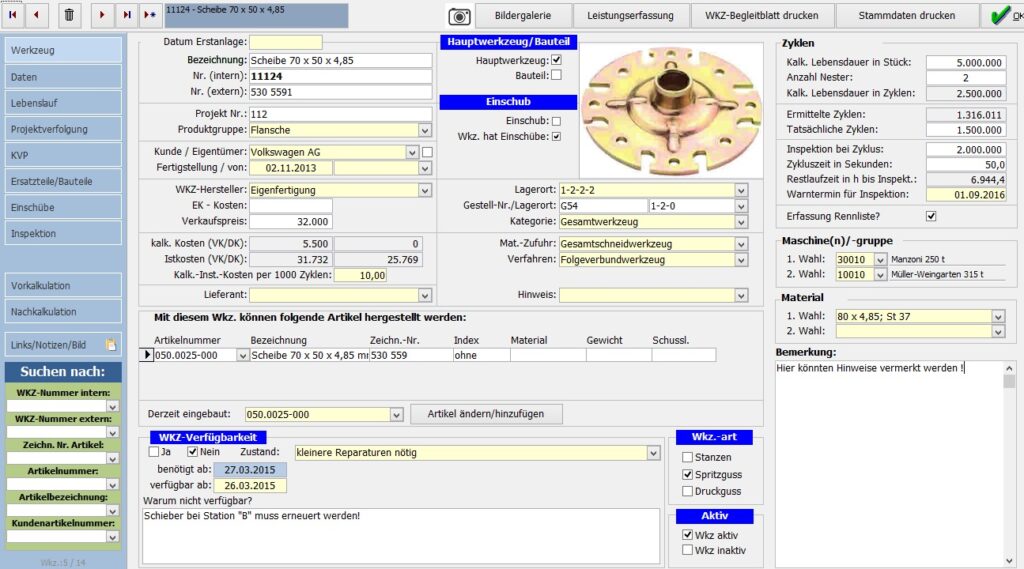

- Documentation of relevant tool master data (with image gallery),

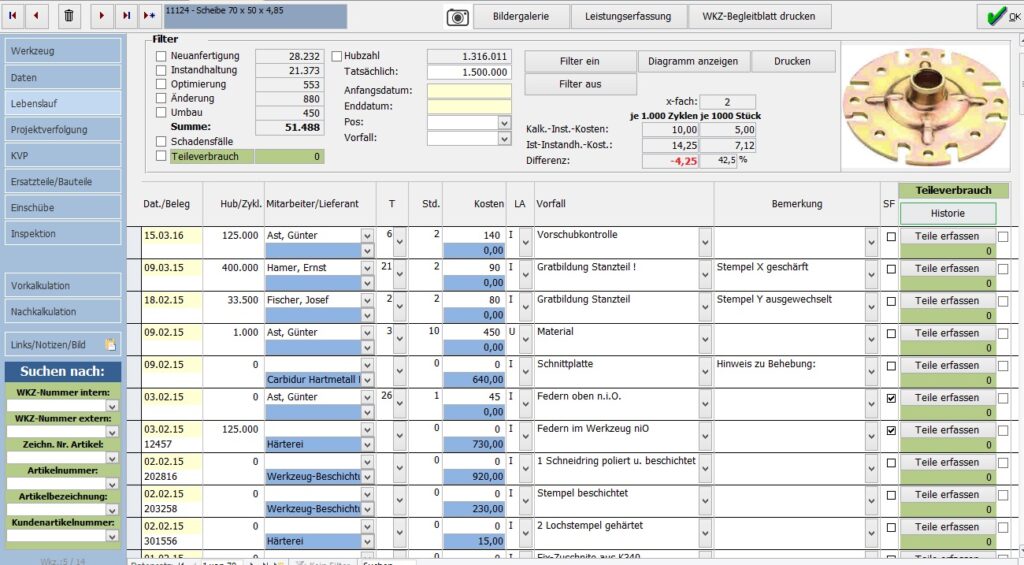

- complete “curriculum vitae” of tool-related events and work performed,

- Recording and reporting faults with solution tips,

- Recording with evaluation of the costs for tool production, maintenance, repair and optimisation,

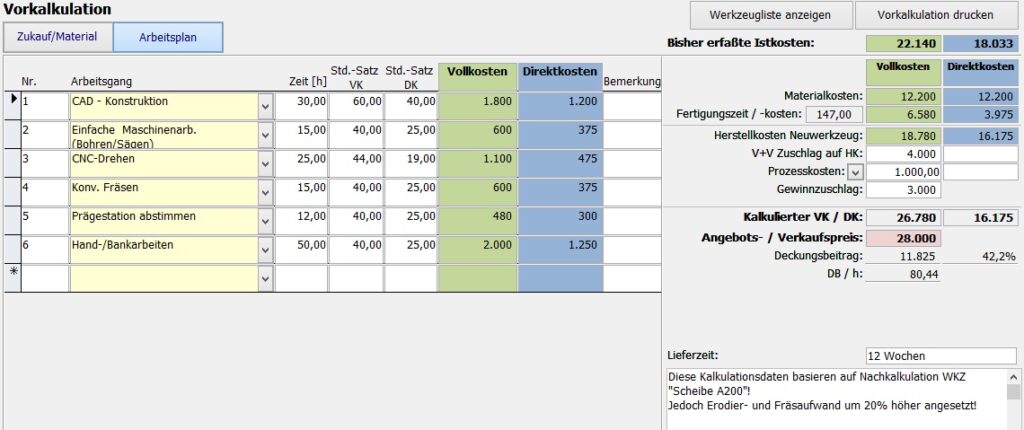

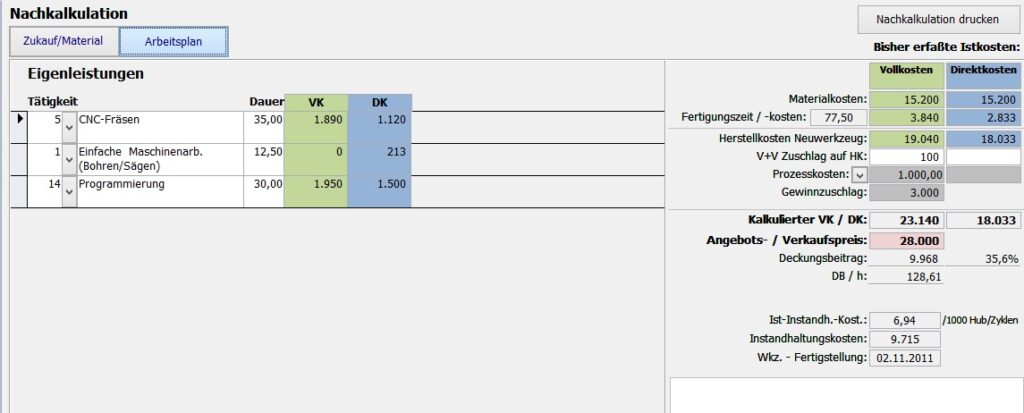

- Tool costing (preliminary and final costing),

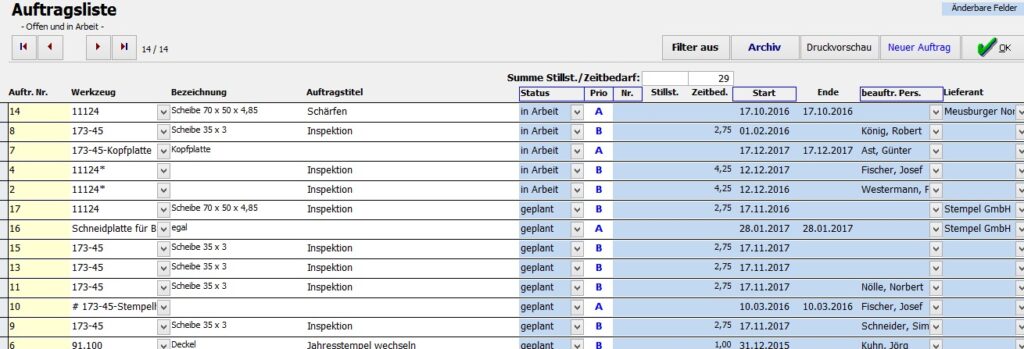

- Documentation of the tool-related setup order,

- Display of tool availability (status message),

- Recording of important wearing parts with ordering information, target and actual stock quantity,

- Creation of individual performance reports for tools and activities,

- Work planning via tool repairs.

Play Video