INSTA – maintenance software and maintenance planner

protects against production downtimes and supports the requirements of the QM systems according to ISO 9001 and IATF 16949.

Play Video

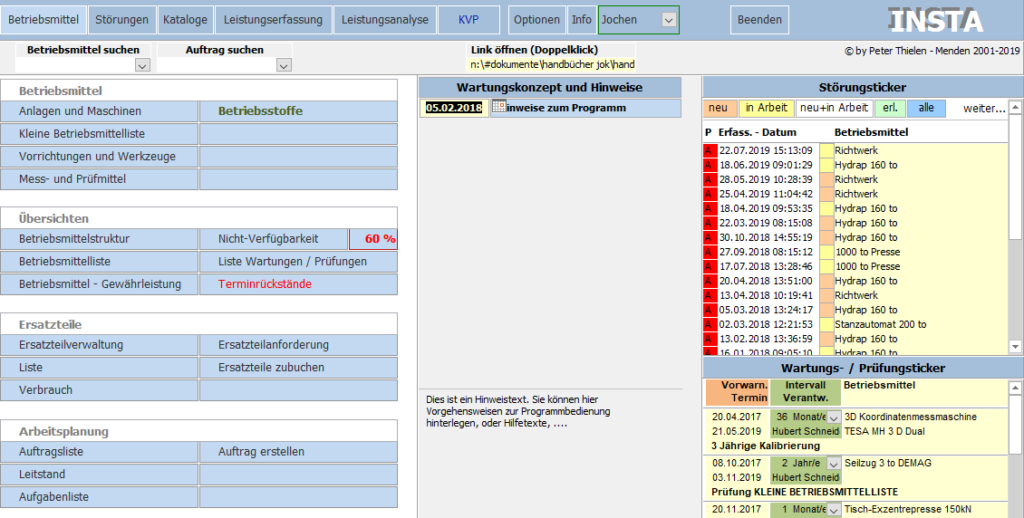

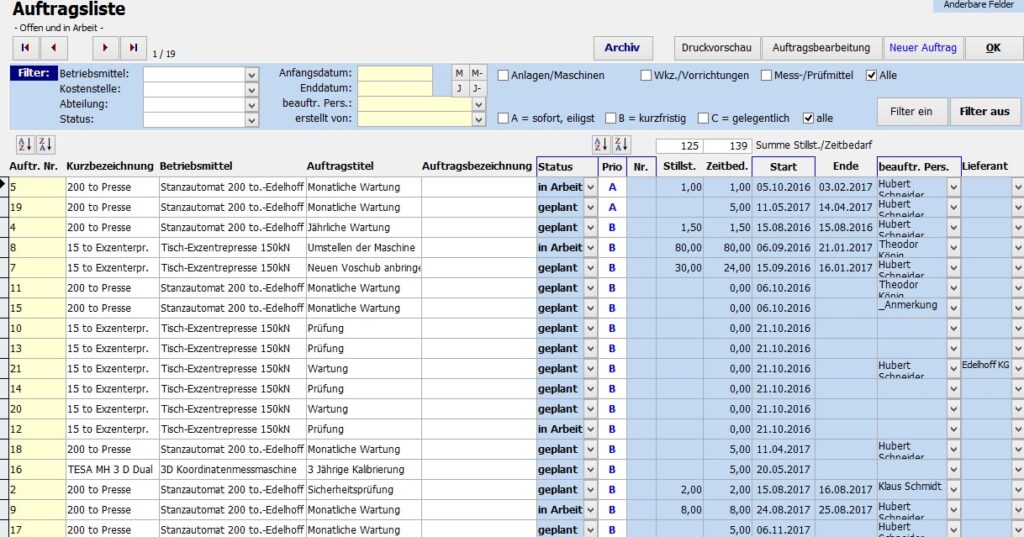

INSTA offers the following functions: </Display of inspection and maintenance dates In the history, machine maintenance and repairs carried out are completely documented. and maintenance plans

- Fault recording and fault processing with solution notes

- automatic fault reporting (optionally by e-mail)

- Information about non-availability due to machine failures

- Information about machine manufacturers, Suppliers and their service points

- Capture and management of the relevant spare parts with inventory management

- Work planning with simple order creation

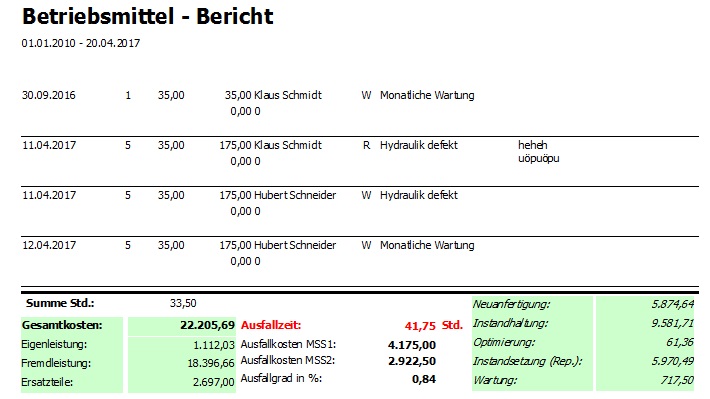

- Maintenance cost and downtime determination (MTBF / MTTR) for all equipment

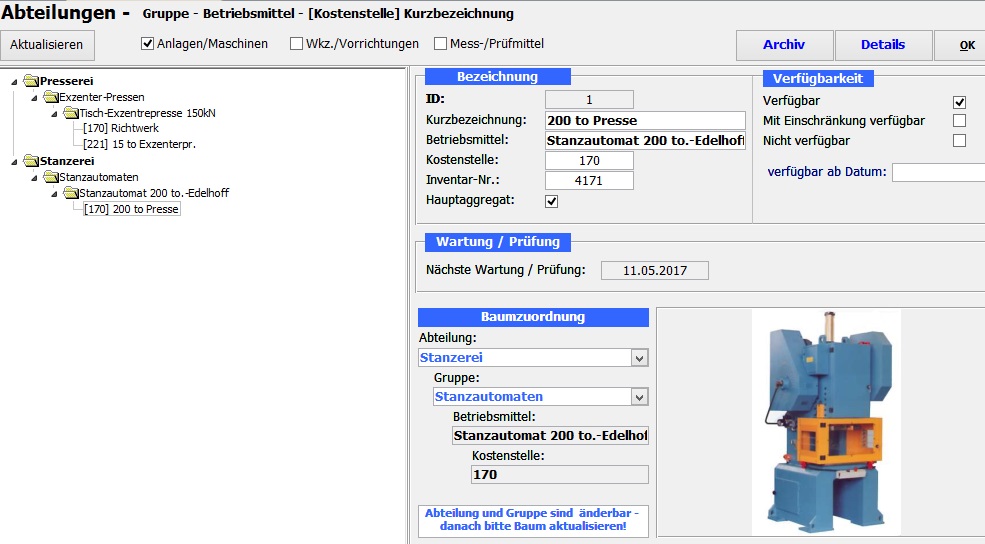

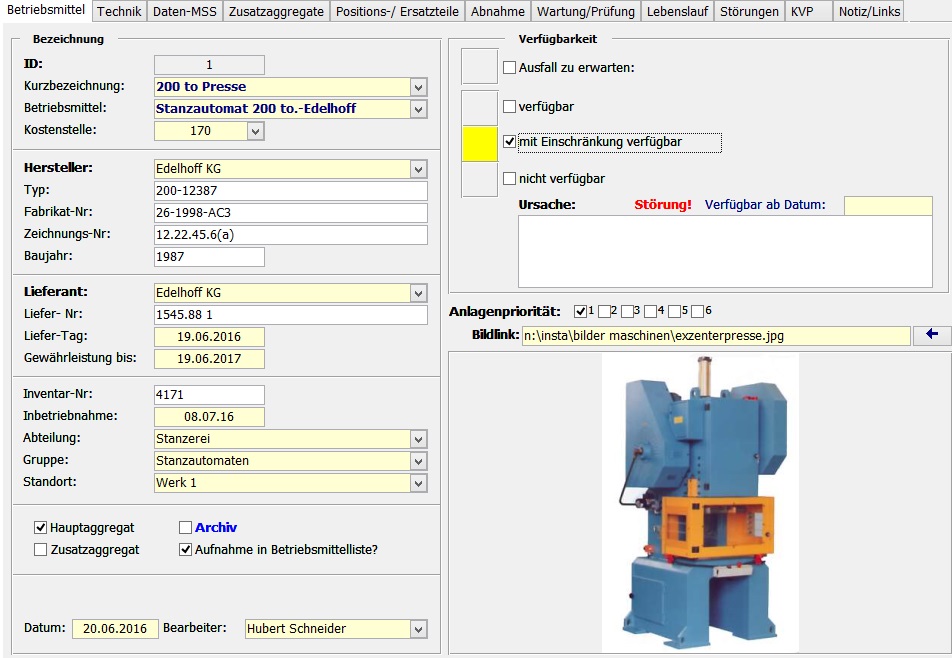

Essential characteristics and the availability of the equipment (here a 200 ton press”) are displayed here. On further tabs, important information can be stored, e.g. about the associated auxiliary units and spare parts (storage location, quantity, supplier, etc.) as well as detailed information on maintenance planning and inspections.